Moisture Expansion Testing

Coefficient of Moisture Expansion (CME) is defined as the fractional change in strain per unit mass variation due to the moisture desorption or absorption. The CME is determined by measuring the moisture content change and the strain change between two moisture equilibrium states. The CME is needed in the design and construction of high-stability structural applications.

PMIC has extensive experience determining the CME in composite plates, tubes, and honeycomb structures with a wide variety of sizes, shapes, temperatures, and humidities. PMIC performs CME testing in a laboratory space engineered to provide the control necessary to perform the environmentally-sensitive procedures.

CME Testing System and Procedure Capabilities

| Coefficient of Moisture Expansion | Capabilities |

|---|---|

| Relative Humidity (RH) | 0 % RH to 95 % RH |

| Temperature Range | 296 K to 348 K |

| (23 °C to 75 °C) | |

| Sample Sizes | Flexible geometry requirements |

| Other Measurements | Axial and transverse expansion of panels |

| Hoop and axial moisture expansion of tubes | |

| Fickian and non-Fickian diffusion coefficients | |

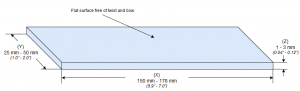

| Standard Sample Size | 177.8 mm × 50.8 mm, see Figure 1. |

| Standard Conditions | 53 % RH, 24 °C |

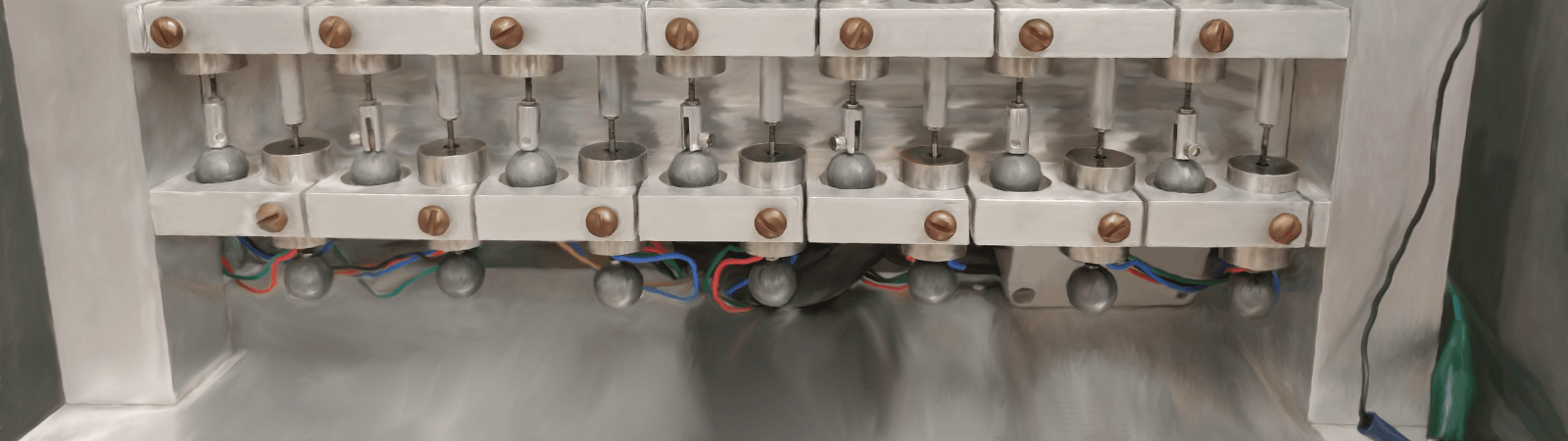

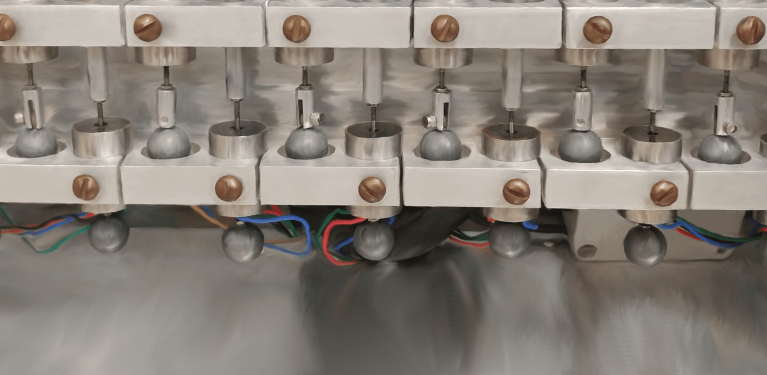

The moisture change is measured using a balance with a resolution of 10-5 g. The strain change is measured with a PMIC dilatometer. This dilatometer uses Linear Variable Differential Transducers (LVDTs) to monitor length change. The dilatometer has a maximum resolution of 76 nm.

CME testing takes place in an environmentally controlled room, to guarantee that humidity and temperature remain constant as the specimens are moved through the multiple stages of testing. The specimens are cleaned and prepared to control absorption, and then dried until their mass is stable to the “fully dry mass.” The customer’s specimens are held in a small container that maintains a constant relative humidity (RH) environment, using the techniques described in ASTM E104 or, in cases where an aqueous solution is not appropriate, alternative methods. Per ASTM D5229, material absorption is monitored according to a preconceived testing plan by a PMIC engineer. Data are provided for the material’s rate of absorption over time at a constant % RH. This continues until the material reaches the “fully saturated mass.”

The specimens are installed in a PMIC CME LVDT chamber with desiccant, and desorption and strain are recorded.

CME ASTM Standards

| ASTM Standard | Name | Property | Material |

|---|---|---|---|

| C272 | Standard Test Method for Water Absorption of Core Materials for Sandwich Constructions | Absorption | Sandwich |

| C481 | Standard Test Method for Laboratory Aging of Sandwich Constructions | Aging | Sandwich |

| C356 | Standard Test Method for Linear Shrinkage of Preformed High-Temperature Thermal Insulation Subjected to Soaking Heat | Shrinkage | Insulation |

| E104 | Standard Test Methods for Maintaining Constant Relative Humidity by Means of Aqueous Solutions | Relative Humidity | n/a |

| D570 | Standard Test Method for Water Absorption of Plastics | Absorption | Plastics |

| D5229 | Standard Test Method for Moisture Absorption Properties and Equilibrium Conditioning of Polymer Matrix Composite Materials | Absorption | Composites |

| E96 | Standard Test Methods for Water Vapor Transmission of Materials | Transmission | n/a |