Dimensional Stability Testing

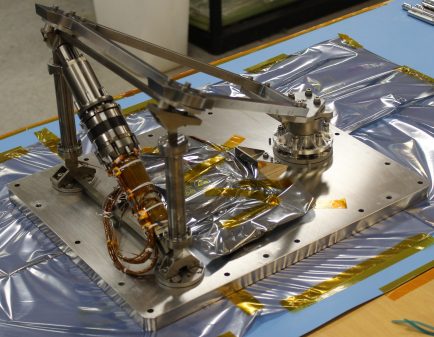

Thermal distortion, such as creep, bend, and twist of structures and components can be analyzed as a function of temperature. Dimensional stability measurements use optical levers and interferometry simultaneously to measure angle and length change. Chambers are customized to the customer’s unique parts (Figure 2) as necessary. Currently, PMIC has chambers for structures up to 2.4 m (8’), as well as powered mechanisms and flight component-capable chambers. The normal temperature range for this testing is 88 K to 458 K (-185 °C to 185 °C) with extended temperature ranges ready for development.

Dimensional stability and thermal distortion testing are critical to assuring engineering precision in limited tolerance designs. Examples include telescopes, optical systems and primary to secondary axes of a tube.

Other tools may include gauge block comparators, modified differential Michelson interferometers, differential LVDT dilatometers, Fraunhofer-Fresnel diffraction-based gages, and Fabry-Pérot interferometers.