ASTM E1225 vs ASTM D5470: When the difference matters

|

|

For thermal conductivity measurements, the guarded-heat-flow methods ASTM E1225 and ASTM D5470 are among PMIC’s preferred methods. PMIC operates several guarded-heat-flow systems, each built slightly different to best meet a variety of temperature, environment, or load specifications. Although ASTM E1225 and D5470 are comparative test methods, the results have low uncertainties, even when using non-standard specimens.

But when a material is determined to be suitable for both ASTM E1225 and ASTM D5470, how does PMIC determine which method to use?

The answer is primarily based on the customer material thickness and the placement of thermocouples.

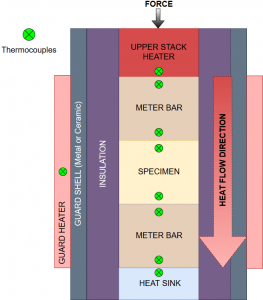

PMIC’s application of ASTM E1225 typically requires thermocouples to be placed in the customer material as shown in Figure 1. PMIC’s application of ASTM D5470 applies guarded-longitudinal-heat-flow to a thin specimen, or stack of thin specimens.

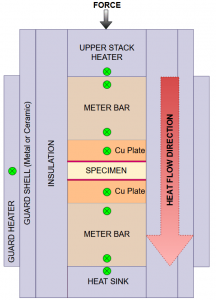

There are sources of uncertainty associated with the absence of temperature sensors to measure the temperature gradient of the specimen. The customer material is sandwiched between copper plates having integrated thermocouples. The copper plates spread heat uniformly over the surface of the specimen. However, as seen in Figure 2, the contact resistance between the copper plates and the specimen cannot be measured. Therefore the actual temperature drop through the specimen may not be accurately represented by the temperature drop that is measured between the two copper plates.

PMIC may advise that a thinner specimen will produce better results due to the material properties. In these cases, the uncertainty from a thicker specimen with very low thermal conductivity, and thermocouples installed (ASTM E1225), is greater than the uncertainty caused by the unaccountable contact resistance and temperature drop (ASTM D5470).